Energy Resource Management

-

Guan Tian Plant's annual electricity saving rate from 2015 to 20241.28%

Guan Tian Plant's annual electricity saving rate from 2015 to 20241.28% -

Fuel substitution29.77%

Fuel substitution29.77% -

Reduced coal consumption48,274 metric tons

Reduced coal consumption48,274 metric tons -

Recycled 22,880 metric tons coal ash100% into CLSM

Recycled 22,880 metric tons coal ash100% into CLSM -

Reduced carbon emissions4,295 metric tons CO₂e

Reduced carbon emissions4,295 metric tons CO₂e

Targets and Progress

Total Water Consumption at Guan Tian Plant

- 2022: 811,448 cubic meters

- 2023: 854,310 cubic meters

Targets

Since 2023, a water conservation plan has been established in accordance with the Water Resource Management Policy, setting water-saving targets for 2024 and implementing measures accordingly.- The cogeneration system at Guan Tian Plant operates with nearly 99% steam condensation and recycling. Depending on the process conditions of steam users, condensate water is recovered and reused in the cooling tower, improving cooling water quality and reducing freshwater consumption. In 2023, over 80,000 metric tons of condensate water were recovered.

- Water intake, discharge, and consumption data for 2022 and 2023 at Guan Tian Plant have undergone limited assurance verification.

Water Resource Management

Taiwan's water resources are scarce, but water is also an essential resource for steam turbines during the power generation process. Thus, TCC attaches great importance to the use of water resources and enhances the efficiency of water usage through effective management, reducing consumption and unnecessary wasting of water resources.

The total intake water of Guan Tian Plant

Water Resource Utilization and Recycling

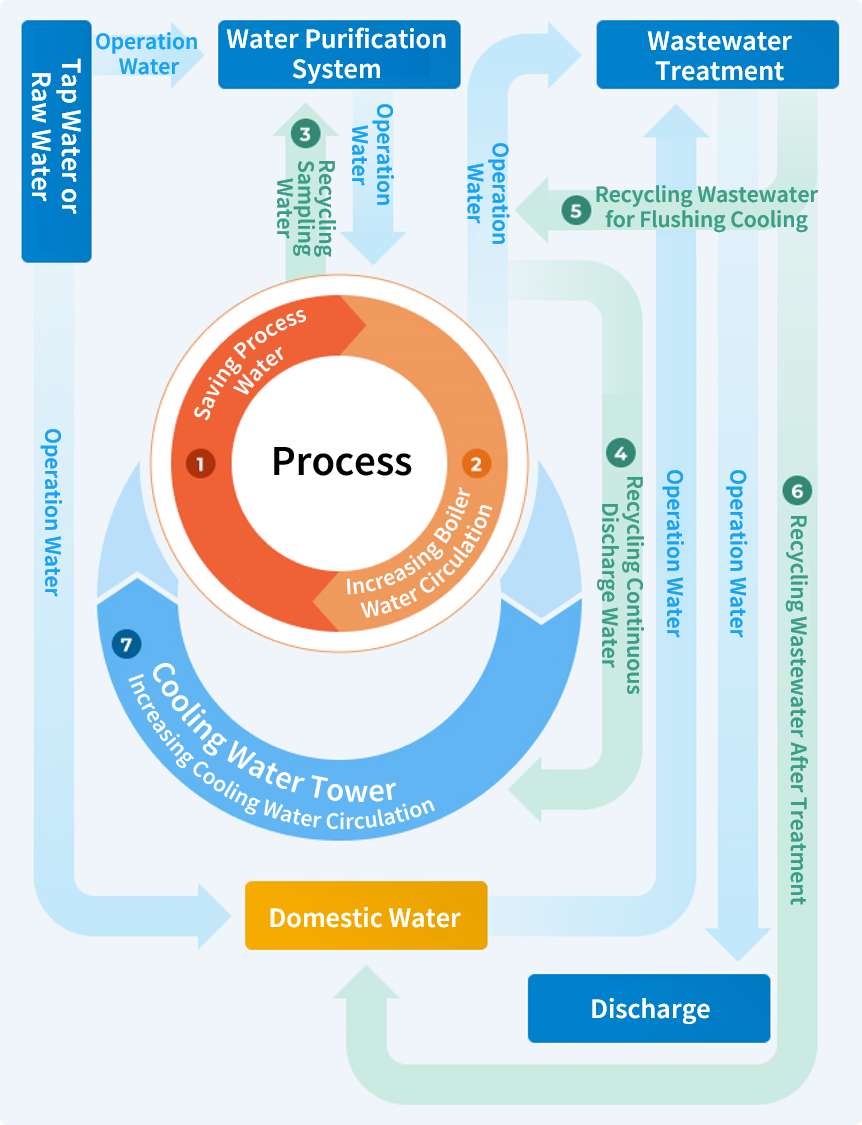

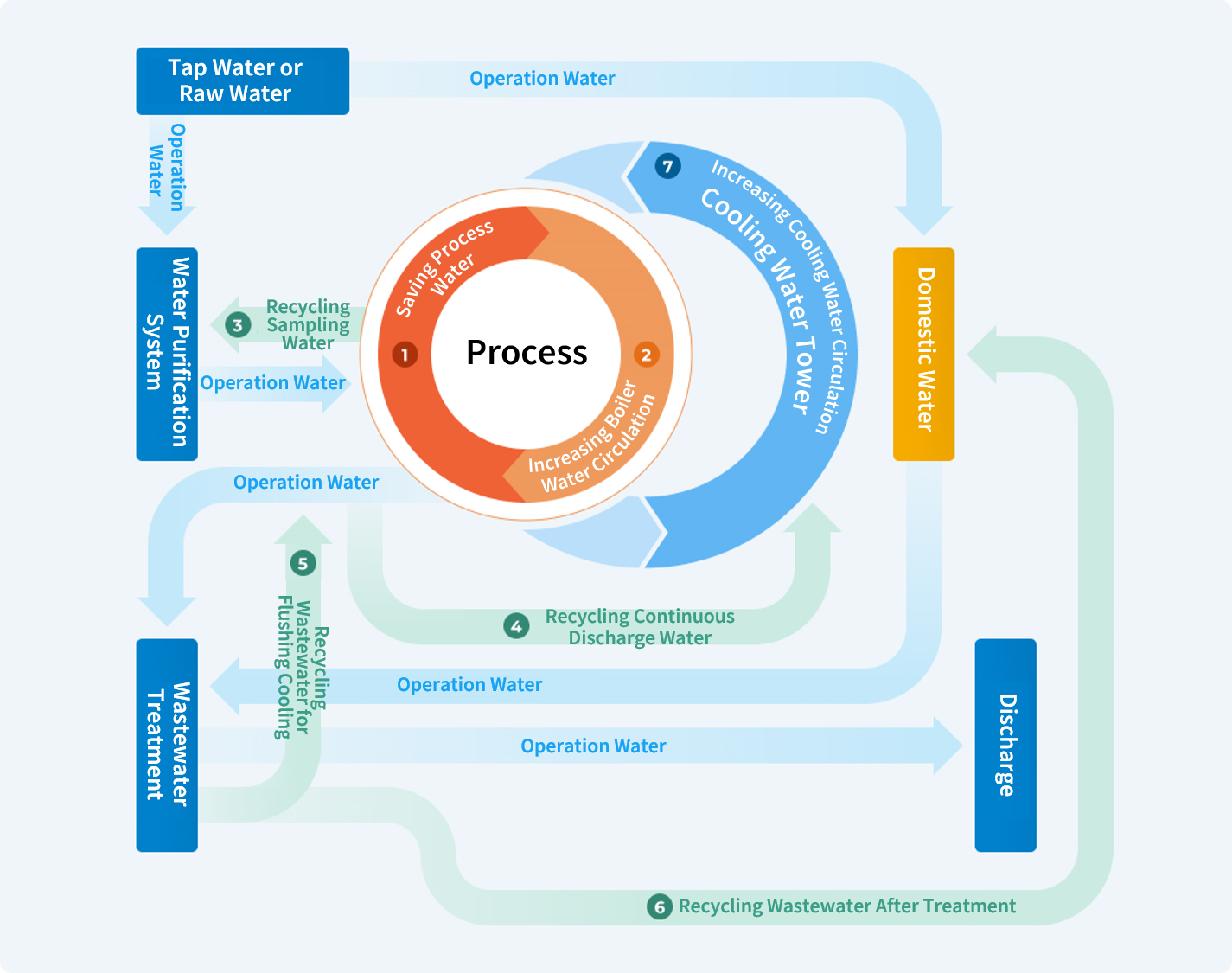

Water Resource Utilization Cycle in Cogeneration Plant

For regular boilers in cogeneration plant, the high-pressure steam created by the boilers will first generate electricity through the power generation process. The remaining steam is then re-heated and divided into high-pressure, medium-pressure, and low-pressure steam according to the in-plant process and users' demands. Subsequently, it is supplied to high-pressure feedwater heaters, low-pressure feedwater heaters, deaerators, heavy oil heaters, and sold to customers in industrial areas for higher energy efficiency. The steam consumption of equipment in the plant is approximately 25% of the steam produced by the boiler. Except for some losses through fugitive emission, the remaining steam can be condensed and recycled.

TCC attaches great importance to the management of water resources, adhering to the principle of no waste policy, while strengthening the recycling of water resources. Under the circumstance of no sales, nearly 99% of the steam in Guan Tian Plant can be fully condensed and recycled without wasting any water resources. When selling steam to customers, depending on the process conditions of the steam customer and the water quality of the condensation, the condensed water after the process is recycled and used in the cooling water tower. Since the quality of condensate is better than that of raw water, it not only improves the cooling tower's water quality but also reduces the usage of raw water. In 2023, approximately 80,000 metric tons of condensate were recycled. Additionally, about 10,000 metric tons of wastewater from continuous boiler blowdown was used. The heat energy is recovered by the heat exchanger and then discharged into the cooling water tower, which can also improve the water quality of the cooling tower and reduce the discharge of wastewater indirectly

Since Guan Tian Plant is located in the Guantian Industrial Park and its production process is power generation, according to regulations, all wastewater generated must be discharged to the Wastewater Treatment Plant in the Guantian Industrial Park for centralized treatment. The wastewater generated by Guan Tian Plant can easily meet the Effluent Standards by using simple pretreatment process. Therefore, in 2017, a recycling water pipeline was added to the discharge pipeline, and the amount of wastewater recycled has gradually increased each year.

Water Resource Utilization Cycle in Guan Tian Plant

Unit:m³

Water-Saving and Water-Recycling Measures

Guan Tian Plant and the invested Star Energy Power, Sun Ba Power, and Star Buck Power all attach great importance to the use of water resources, as each plant continues to invest in water-saving and water recycling measures. For cogeneration plants or natural gas combined recycling plants, the main water-saving and water-recycling measures are as follows.

Water-Saving and Water-Recycling Measures

Saving Process Water

Reduce process water consumption through unit adjustment, such as modifying the flushing/draining water tank discharge piping system of heat recovery boiler and add shut-off valves and control systems to prevent steam from accidentally entering the water tank, resulting higher cooling water consumption.

Increasing Boiler Water Circulation

Pure water in the boiler is continuously circulated and boiled, which is prone to scaling due to high temperature. It is necessary to replace the circulating water through continuous discharge to maintain the water quality in the boiler. Chemicals can also be added to maintain boiler water quality, increase the number of cycles and remove sludge, increasing boiler efficiency and reducing boiler water discharge.

Recycling Sampling Water

A boiler sampling water recycling system is added to recover the sampling water of the boiler water and the pure water used for flushing the instruments in the sampling room. The recycled sampling water is used as boiler water after being filtered by the ion exchange resin in the water purification system.

Recycling Continuous Discharge Water

Since the quality of boiler condensation and continuous discharge water is better than that of raw water, they are directed into the cooling water tower for reuse once their heat energy has been recovered by the heat exchanger. This can improve the water quality of the cooling water tower and reduce the discharge of wastewater.

Recycling Wastewater for Flushing Cooling

Changed the water source of flush cooling for the auxiliary boiler and the waste heat boiler. The cooling water originally supplied by raw water tank is replaced by the recycled water from the wastewater system, reducing the consumption of raw water for flush cooling.

Recycling Wastewater After Treatment

Part of the effluent in the wastewater treatment facility is recycled after its treatment, serving as irrigation for green spaces within the plant, cleaning coal yard/suppressing dust, etc.

Increasing Cooling Water Circulation

When the cooling water tower is in operation, the water will reduce due to evaporation and scattering. Moreover, impurities in the water will accumulate, resulting in scaling that affects the operation. Therefore, it is necessary to drain the water frequently to maintain the water quality. Chemicals can be added to adjust the water quality, minimize the scaling, increase the concentration ratio, and reduce the discharge of cooling water.